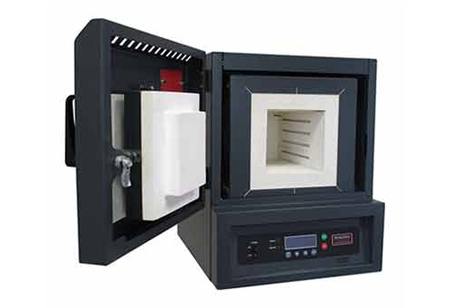

High Temperature Furnaces

Bogie hearth

furnaces equipped with SiC rod heating can be used in the production of

technical ceramics, especially for sintering at working temperatures up to

1550 °C. The WHTC product line with especially robust design can hold

heavy charges including kiln furniture. The furnace chamber is equipped with high-quality insulation made of high-temperature fiber blocks. The bogie

insulation is structured in multi-layer lightweight refractory bricks on the

heating chamber side.

The furnace is

heated along both sides by vertically installed SiC heating rods. This heating

technology permits processes requiring working temperatures above 1350 °C

which cannot be achieved with wire heating elements. The SiC rods are controlled

by the thyristor controller which counteract the aging of the heating elements by

means of automatic power compensation.

- Tmax 1550

°C

- Dual shell

housing with rear ventilation provides for low shell temperatures

- Swing door hinged

on the right side

- Heating from both

sides via vertically mounted SiC rods

- Thyristor

controllers with automatic output compensation counteract the aging of SiC rods

- Multi-layer

insulation with high-quality fiber modules on the heating chamber side

- Bogie for heavy

loads lined with lightweight refractory bricks

- Bogie hand driven

on rubber tires

- Motor-driven

exhaust air flap on the furnace roof

- Over-temperature

limiter with adjustable cutout temperature for thermal protection class 2 in

accordance with EN 60519-2 as temperature limiter to protect the furnace and

load

- Defined

application within the constraints of the operating instructions

- NTLog Basic for

Nabertherm Controller: Recording of process data with USB-flash drive

Additional equipment

- Safety concepts

- Exhaust air and

exhaust gas piping

- Thermal or

catalytic exhaust cleaning systems

- Process control

and documentation via VCD software package or Nabertherm Control Center (NCC)

for monitoring, documentation, and control

- By Silcarb

No comments:

Post a Comment